HISTORY

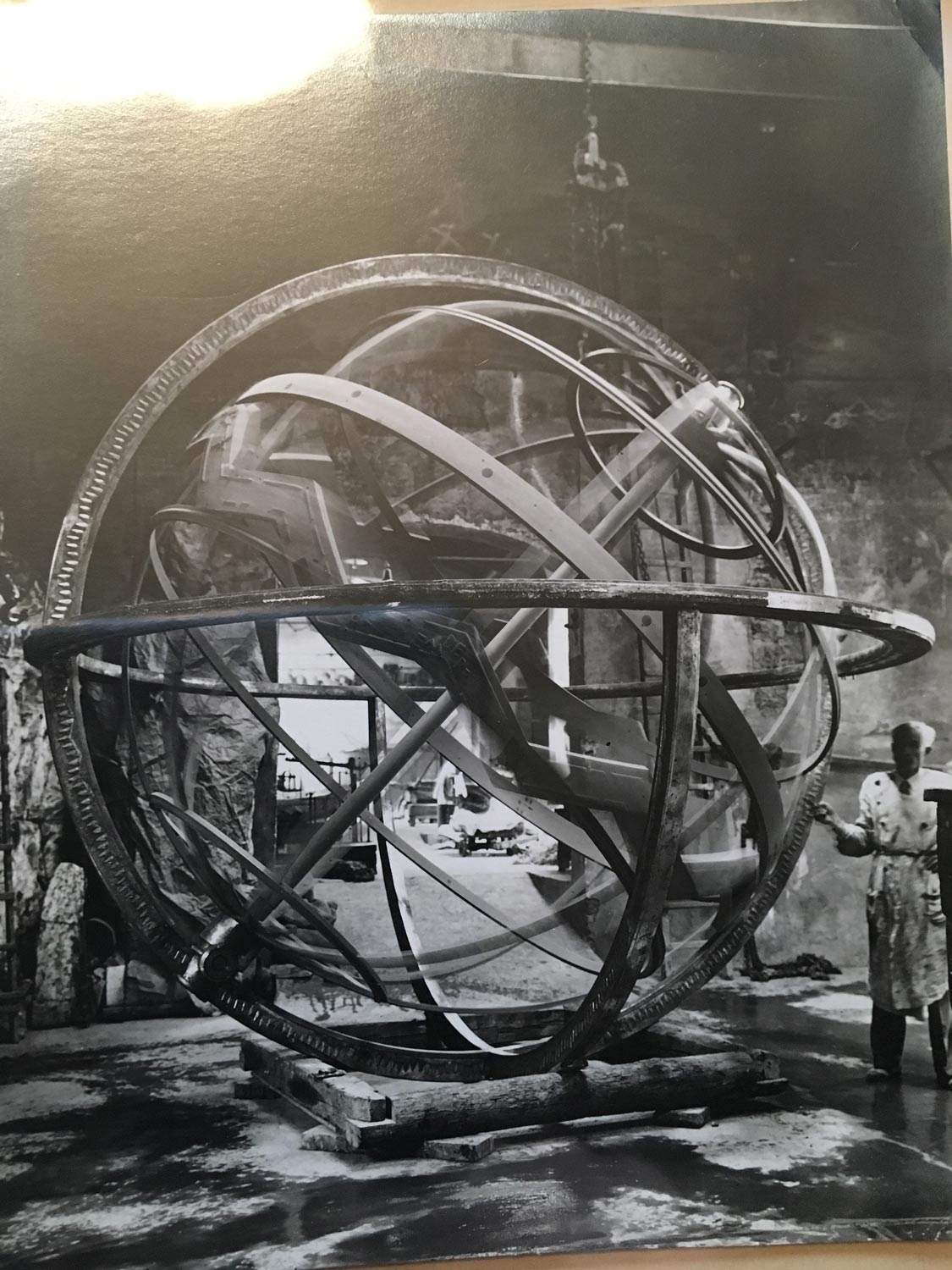

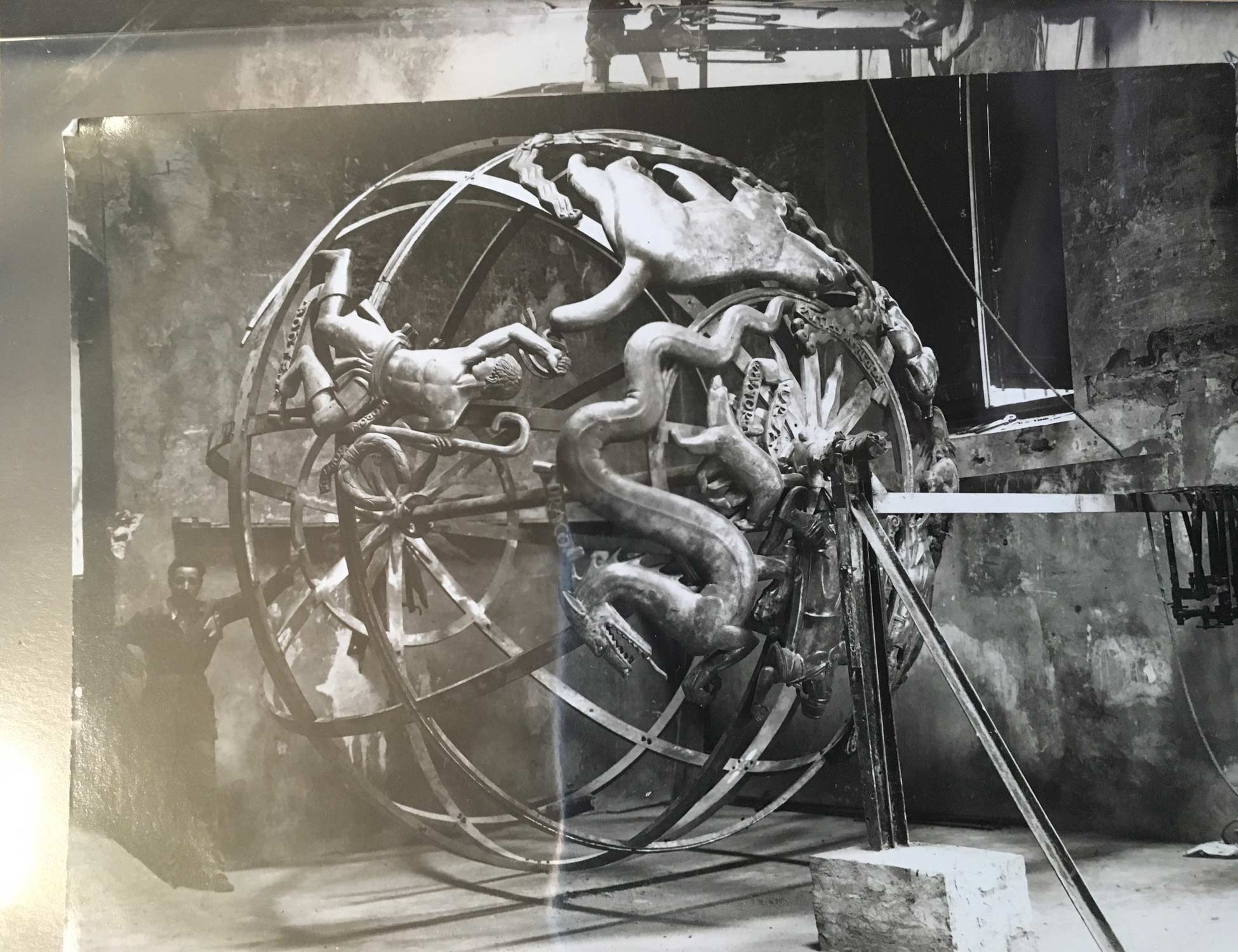

The American Woodrow Wilson Foundation, whose president was Franklin Delano Roosvelt, (Fig. 1) contacted the American sculptor Paul Manship in 1935 (Fig. 2) for the creation of a monument to be placed in the park of the League of Nations building in Geneva, Switzerland. Manship proposed a large bronze Celestial Sphere with an iron frame, the surface of which was covered with bronze sculptures of the zodiacal constellations cast in lost wax and gilded; the sphere must have had an astronomical rotational movement as the earth’s axis. The casting of the monument ended in 1939, a year after the inauguration of the building (Fig. 3). Paul Manship created in 1934 the famous gilded sculpture for the Rockefeller Center in New York “Prometheus” (Fig.3a). Shortly after the inauguration, the rotation mechanism of the Sphere blocked, and the atmospheric conditions altered and abraded the gilding of the sculptures (Fig. 4).

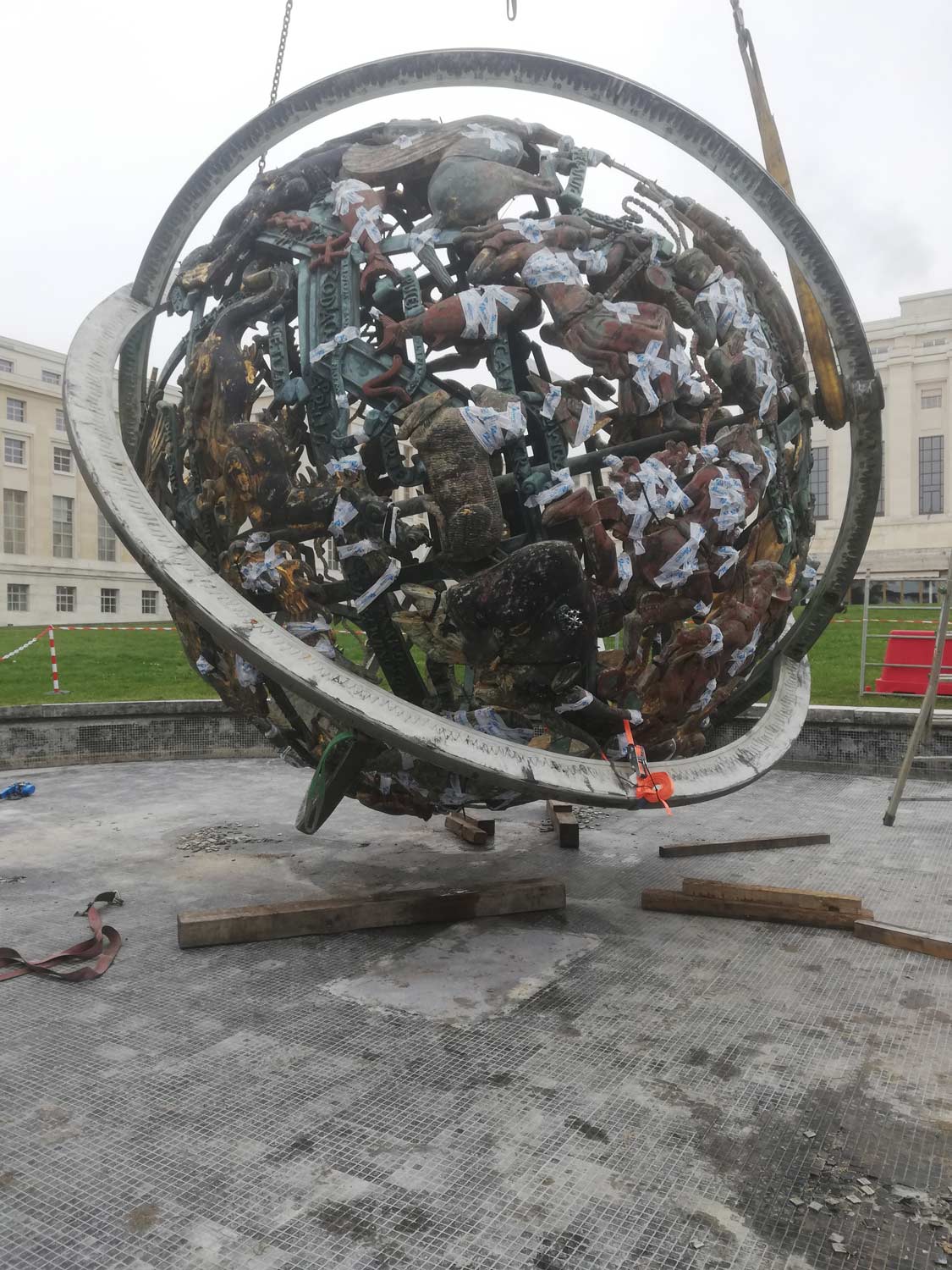

In May 2019, the management of the United Nations Building issued a tender for the restoration of the Sphere, Ferdinando Marinelli together with Carlo Lanaro of Lanaro Steel Technology were invited to participate at a cognitive investigation of the state of decay of the Monument (Fig. 5).

Analysing the state of decay of the work, they study the best way to restore the Sphere to bring it to its original beauty and functionality. The damages that a clumsy restoration made in 1983 had added improper welding to oxidation, sulfation, loss of gilding, rusting of the parts of the iron frame due to bad weather; were also clearly seen concrete filling of the bronze base and other sculptures.

After an interview in Geneva with the UN Commission in charge of following the restoration of the monument, the latter asked to see and analyze the previous restoration that the Ferdinando Marinelli Foundry had carried out on the bronze sculptures of the Tritons Fountain in Valletta, Malta (Fig.6).

In February 2020 the restoration of Paul Manship’s “Celestial Sphere” was entrusted to the Ferdinando Marinelli Artistic Foundry of Florence, with Lanaro Steel Technology as subcontractor for the iron parts to be replaced with stainless steel and for the mechanical structures.

From the historical photos of the UN it has been confirmed that originally the skeleton of the Sphere to which the lost wax and then gilded bronze sculptures were fixed was in fact made of iron.

(Fig. 7-8)

WORK BEGINNING

The first phase was to perform a 3D scans of the Monument (Fig. 9).

We then proceeded with the detachment of the Sphere from the base and its locking to a special frame built for its transport to Italy (Fig. 10-11- 12- 13-14).

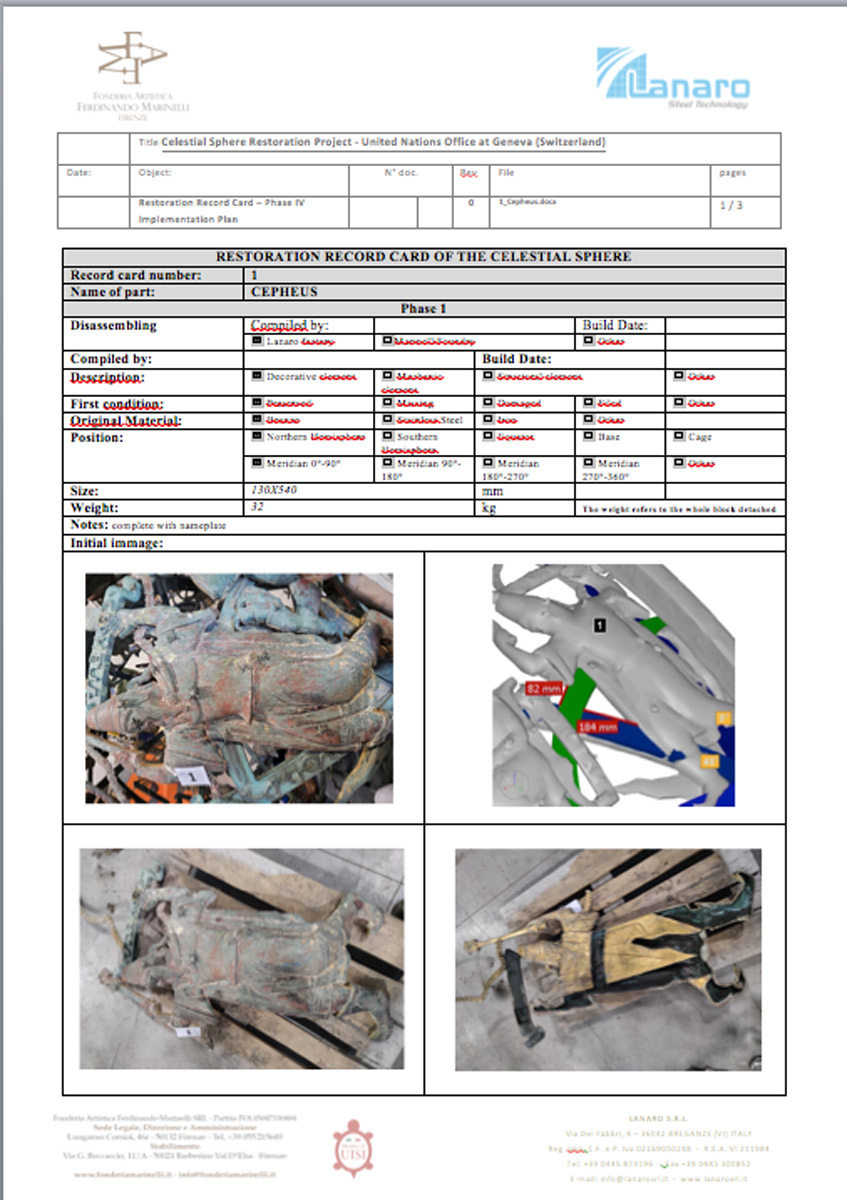

Upon arrival of the Sphere in the Foundry, the detachment of the bronze sculptures from the iron skeleton began (Fig. 15-16-17), Then the photographic cataloging (Fig. 18), and filing (Fig. 19).

THE RESTORATION

After some sandblasting tests on the surfaces of the bronzes with sands of different granulometry (Fig. 20), the surfaces of the sculptures have been cleaned to their primitive state, eliminating the remains of gilding and the underlying bole (Fig. 21).

Some sculptures, filled with concrete in the 1983 restoration, were opened and emptied, and then closed and restored to their original appearance (Fig. 22-23-24-25).

The cleaning of the surfaces also allowed to highlight cracks and casting defects in the sculptures so that they could be repaired with welding (Fig. 26).

THE GILDING

Before applying the gold, the parts that were originally patinated were re-patinated (Fig. 27).

Two coats of bole were then applied, yellow and red, as originally (Fig. 28-29), on which the pure gold leaf was spread with the “a missione” system.

(Fig. 30-31-32-33).

MISSING PARTS

Some parts of the sculptures had been detached from the Celestial Sphere in the past, and been lost.

re-sculpt the models basing on the old photos provided by the UN, creating the waxes to be cast in bronze:

clay modeling based on archive photos (Fig. 34-35),

execution of the negative cast on the clay model (Fig. 36-37),

execution of the wax from the mold and retouching (Fig. 38-39-40-41-42),

bronze casting, assembly and cleaning (Fig. 43-44),

patination, varnish with bole, gilding (Fig. 45).

THE STARS

The bronze sculptures, all depicting celestial constellations, had lost almost all of the stars of different sizes fixed on the surfaces. It was necessary to recreate the models, cast them, work them and chrome them to replace them, as requested by the client:

one size star model, (Fig. 46),

processing of the cast stars (Fig. 47-48),

drilling and breading of the stars (Fig. 49-50),

chrome plating sample (Fig. 51),

chrome stars (Fig. 52-53),

turning of the threaded pins for fixing the stars to the bronze sculptures (Fig. 54).

THE ASSEMBLING

The bronze structure supporting the sculptures of the constellations was restored, patinated and gilded (Fig. 55, 56).

Inside the external supports (equatorial and longitudinal circumferences), the iron bars were replaced with those of stainless steel, and the gilding of the two circumferences (Fig. 57, 58).

The original electro-mechanical parts with numerical control mechanism for the rotation of the entire sphere have been replaced (Fig. 59, 60).

Then began the long operation of repositioning and fixing all the constellations on the bronze structure (Fig. 61, 62, 63, 64).

At this point, it was necessary to carry out delicate balancing tests on the entire monument, applying small balancing weights, to allow a perfect and homogeneous rotation of the sphere itself (Fig.65).

Then the rotation test of the completed sphere took place with a UN Manager. (Fig.66)